Usage:

The brass vertical air vent is used for exhausting air automatically from hot and cold water pipeline systems, pressure vessels and in central air conditioniung. It can prevent water overflow and accumulation of air in pipes which impedes the flow of water. The maximum working temperature is 120°C (248°F), the maximum working pressure is 1.6 Mpa (235 psi) and the acceptable working fluids are water and antifreeze mixtures with water.

Features:

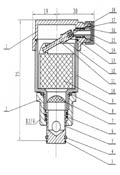

Made with a red hot forging process. Includes filtering device, high sensitivity, has high reliability and a long life-span.

Installation:

The air vent should be mounted vertically in the top of the system. For hot water heating systems it should be installed at the top of the end portion of the piping system.

Prior to installing, check to be sure all seals and gaskets are in place and not broken. In-tact O-rings are essential to prevent fluid loss.

Install the air vent by securing the seat first, then tighten the valve to the seat. Do not overtighten. The gaskets make a good seal by hand tightening. After the unit is installed, release the small end cap to let air out. Under the cap is a a screw which can be loosened our tightened for controlling the pressure in which air is allowed to escape. The end cap uses a gasket to prevent fluid from coming out, and may also be tightened to control how much air flow is allowed through.

If cleaning is needed, close the end cap prior to removing from the piping. Do not remove the seat from the piping. Simply remove the valve from the seat. The built-in check valve will prevent fluid from escaping the system.

If the working fluid used is of poor quality, the air vent should be checked regularly. Preventive measures should be taken to avoid rust and corrosion which could lead to leakage.

Air Vent Specifications Sheet

Warranty: 2 Years

|